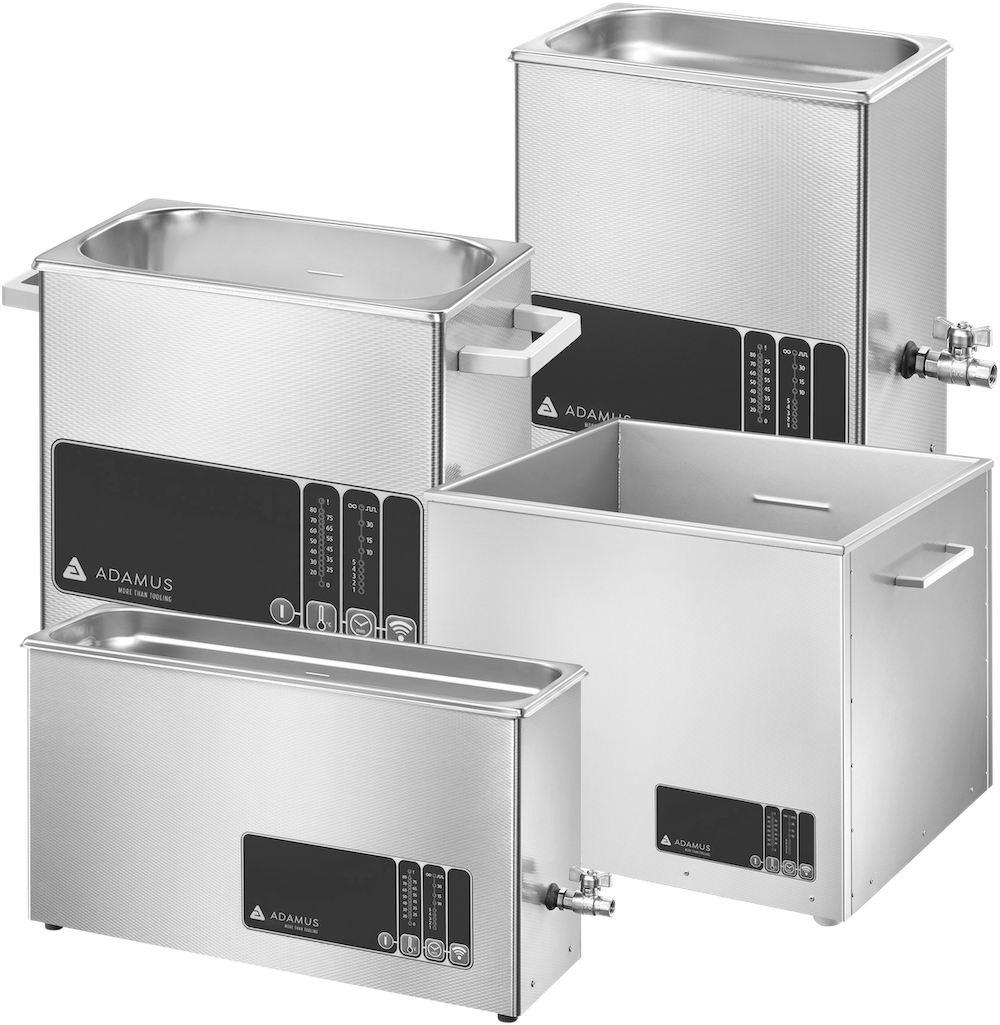

Benefits of ultrasonic cleaning

The recommended method of cleaning punches and dies is the one, which cleans compression tooling perfectly in a short time. It should be able to deal with most types of dirt, even in hard-to-reach places. Cleaning should not cause any damage to the surface of delicate punch tools. All these criteria are met by ultrasonic cleaning.

Ultrasonic cleaning effectively removes post-production contaminants and residues left by grinding and polishing agents, greases, chips and filings. The cavitation generated by ultrasound works intensively and ensures very good results. Ultrasonic cleaners do not cause any damage to the surface of cleaned items.