MORE THAN CLEANING.

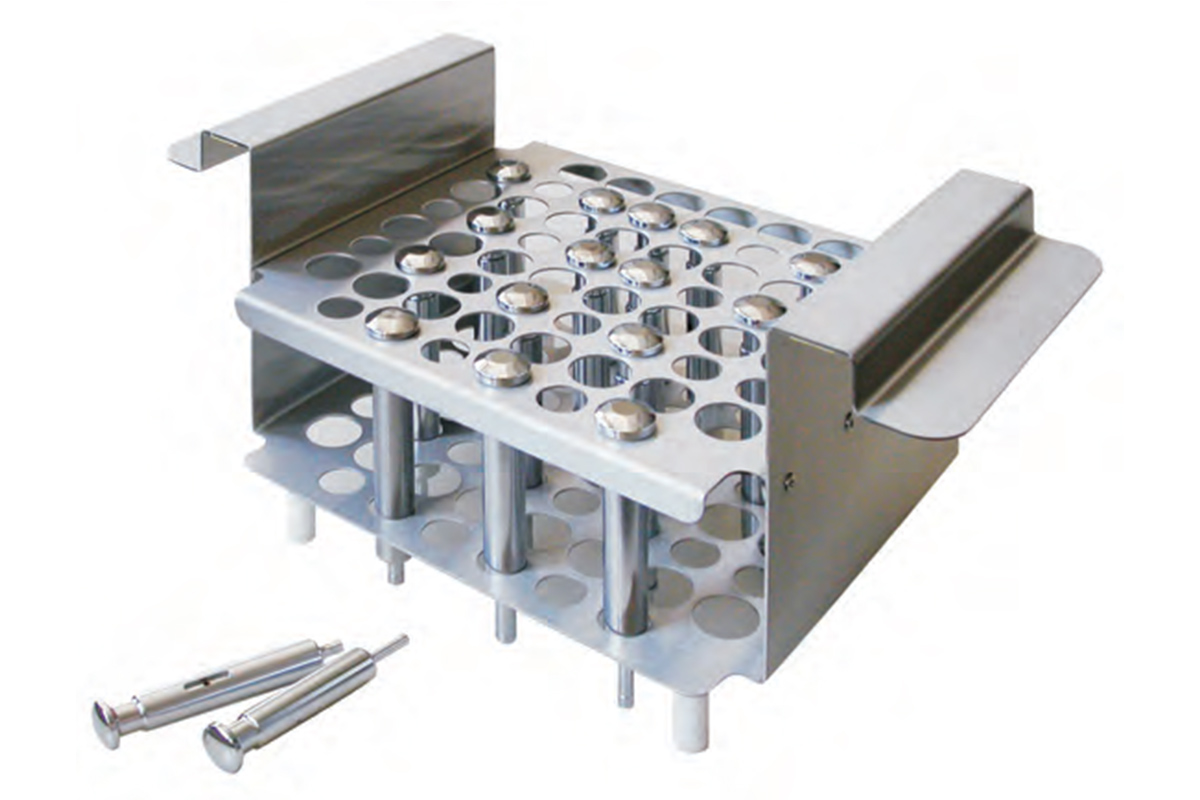

Ultrasonic cleaners from the USC series by Adamus are efficient and functional devices that, owing to their high efficiency, accuracy, simple operation and quick work effects, are widely used in all industries and sectors.

The USC series cleaners handle every kind of dirt, even in hard-to-reach places.

Advantages of Ultrasonic Cleaner

- They reduce cleaning time by up to 90%,

- They require minimal operation control,

- They are easy to install,

- They do not require maintenance,

- They do not cause any damage to the cleaned surfaces.

Ultrasonic cleaning make it possible to get perfectly clean items in less time than cleaning with conventional methods, such as manual or spray cleaning.

Ultrasound effectively removes impurities such as grinding and polishing pastes, abrasive, chips and filings, greases and cooling emulsions. The phenomenon of cavitation generated by ultrasound has a very intense effect which provides excellent results. Despite the strong impact, cleaning with ultrasonic cleaners does not cause any damage to the surface of the cleaned elements.

Operation of ultrasonic cleaners requires minimal control, therefore it can be performed by unqualified personnel. The simple construction of the cleaners does not require any special maintenance procedures.

Ultrasonic Cleaner Series by Adamus

All Ultrasonic Cleaner series models are made of stainless steel, which guarantees resistance to corrosion and mechanical damage. Adamus cleaners are very well suited for professional use. They are characterised by the use of solid materials, careful craftsmanship with attention to detail, as well as easy operation. Most Ultrasonic Cleaner models are equipped with a drain tap that facilitates cleaning of the ultrasonic cleaner and emptying the tank.

Ultrasonic Cleaner

- 4-step operation,

- Heating range from 20 to 80 °C,

- Thermostatic control,

- LED display for set and current temperature,

- Optical signal in case of temperature excess,

- Clock for counting the working time or continuous work,

- Continuous oscillation of the SweepTec ultrasonic wave,

- DEGAS function: setting of pulsating sound for removing unwanted air bubbles displayed on the LCD panel,

- Stainless steel housing protected against splashing,

- The highest possible safety class: IP 33.

Even greater efficiency, owing to the DEGAS function

The DEGAS function removes air, including carbon dioxide from liquids, which causes the formation of more cavitation bubbles. The DEGAS function increases cleaning efficiency by over 30%.

Even faster cleaning, owing to SweepTec technology

The SweepTec function ensures that ultrasound generators work at different frequencies, which results in even distribution of ultrasonic waves, and thus faster removal of dirt from the surface of the cleaned elements.

Advantages of ultrasonic cleaning

- Longer life of the cleaned elements, owing to the gentle and accurate operation of the ultrasonic cleaners

- Fast cleaning process time

- Economical use of water, chemicals and electricity

- It is not possible to damage the cleaned elements and their surfaces

- Excellent cleaning quality even in hard-to-reach places

How does an ultrasonic cleaner work?

A generator is installed in each sonic cleaner which emits ultrasonic waves. The waves move in the tank, causing alternating low and high pressure zones.

During the low pressure phase, microscopic, pulsating bubbles are formed, which first grow and then implode (collapse).

Implanting bubbles cause a shock microwave, which breaks the bonds between the dirt and the surface and reaches every gap, cavity, nook.

Possibilities of using ultrasonic cleaners

Ultrasonic cleaners are used to clean surfaces made of metals and their alloys, plastics, glass, etc. Sonic cleaners are a great solution for cleaning heavily soiled as well as delicate items.

Industry

- Cleaning before powder painting, galvanizing (degreasing),

- Cleaning, degreasing after hardening,

- Cleaning after pressing,

- Cleaning of parts from serial production after machining,

- Cleaning of transport containers,

- Cleaning of components,

- Cleaning of filters,

- Cleaning after polishing,

- Cleaning of radiators,

- Cleaning of forms,

- Cleaning of castings.

Regeneration

- Cleaning of engine components,

- Cleaning of gearbox components,

- Cleaning of turbine components,

- Cleaning of injection pump components,

- Cleaning of injection elements,

- Cleaning of rims and wheels with a tire.

Laboratories, hospitals, dentistry, prosthetics

- Cleaning of medical and laboratory tools (cuvettes, pipettes, bioanalyzers),

- Degassing of liquids,

- Cleaning of dentures,

- Cleaning of dental instruments,

- Cleaning of surgical instruments (endoscopes, gastroscopes, etc.).

Jewelry, watchmaking, numismatics

- Removing polishing paste and casting remains from products,

- For cleaning soiled products,

- Regeneration of components.