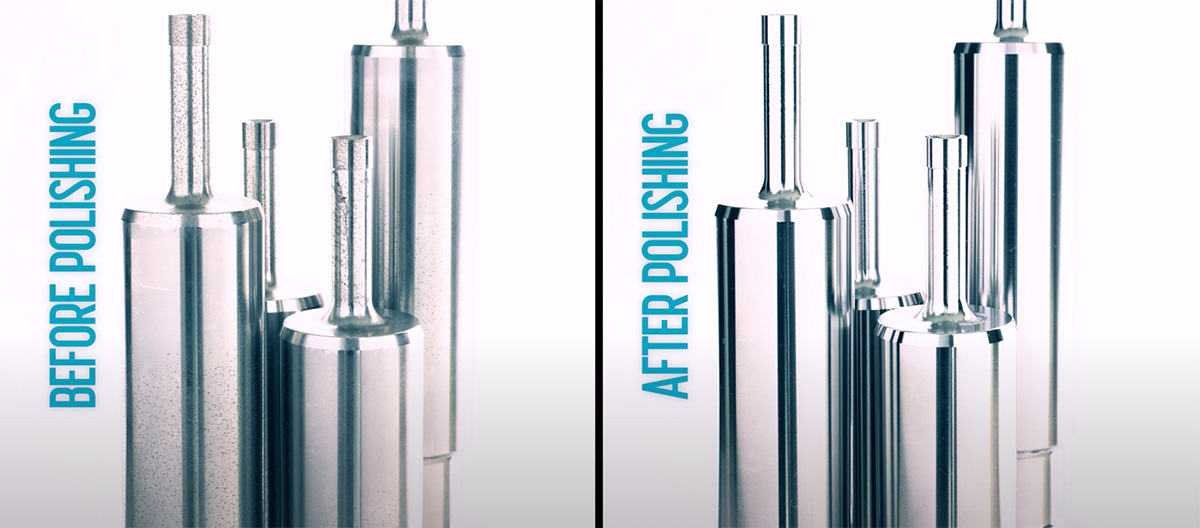

Pharma P&D series automatic polishers are an efficient and state-of-the-art solution for optimising the polishing process and maintaining compression tooling. The machines are designed to polish the largest number of punches and dies in the shortest possible time, while ensuring the highest quality and accuracy.

Pharma P&D polishers have been designed in line with the latest engineering standards. Made of stainless steel, with a simple design and intuitive control panel, they are easy to operate and do not require high-level qualifications.